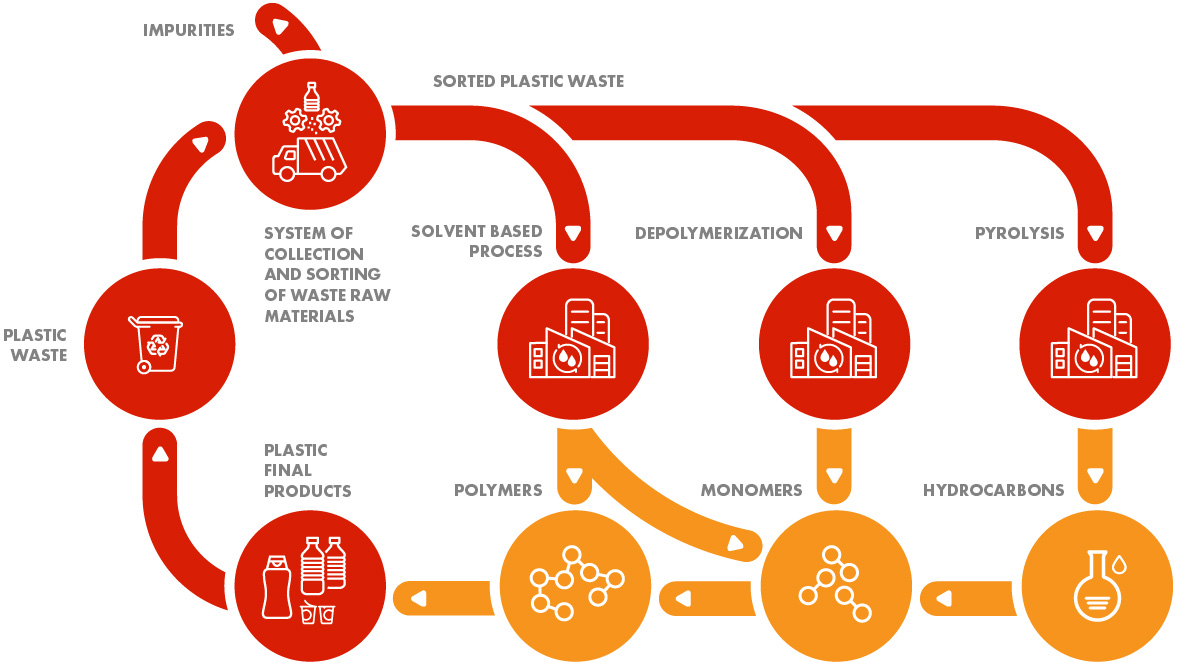

Chemical recycling is the process of recycling waste plastics by changing their chemical structure and converting them back into substances that can be used as raw materials for the re-manufacture of plastics or other products in the chemical industry. Chemical recycling technologies include solvolysis (purification of polymers using solvents) or depolymerisation (decomposition of polymers into monomers) or pyrolysis (thermal decomposition into a mixture of hydrocarbons). The products from these technologies can then be further processed by conventional processes into certified circular plastic products that can be used for more demanding applications such as automotive products, or cosmetic or food packaging.

Within the ORLEN Unipetrol Group, our R&D activities include both research on pyrolysis and research on solvent-based processes. In pyrolysis, a pre-treated feedstock (sorted plastic waste) is fed into a plant where, at high temperatures and without oxygen, it is decomposed into hydrocarbons that can be further used as part of the injection for petrochemical production. Solvent processes take advantage of the different solubility of specific plastics in order to break them down into monomers, or to remove those impurities and contaminants that prevent their reuse in demanding applications.

Key advantages of chemical recycling

1. It also allows the processing of less easily recyclable waste plastics such as multi-species plastic mixtures or waste plastics with higher levels of different types of contamination.

2. This process allows the production of products from recycled plastic that are of the same quality as products made from so-called virgin plastics.

3. Promoting a circular economy by reducing the need for fossil resources

The strategic goal of the ORLEN Capital Group is to increase recycling capacity (mechanical and chemical recycling) to 250,000 tonnes of waste plastics per year by 2035. In the ORLEN Unipetrol Group, we plan to produce mainly polypropylene (PP) and high-density polyethylene (HDPE) by chemical recycling, thus meeting not only the requirements of the upcoming legislation but also the requirements of our customers who already use Liten (HDPE) and Mosten (PP) products. In 2028, we intend to commission our own pyrolysis unit with a capacity of between 15 and 35 thousand tonnes of plastic waste per year as part of our plastic circularity targets.